Airbus in Europe

Our presence in Europe

Airbus in Americas

Our presence in the Americas

Our governance

Striving for transparency

Airbus' Corporate Governance ensures that Airbus is managed according to our Regulating Laws and Articles of Association, and evolves in order to match our growth ambitions, meet our obligations and reach the goals we set ourselves.

Airbus' top-level governing body is the Board of Directors. Responsible for the management of Airbus it delegates the day-to-day management to the CEO who fulfills this task with the support of the Executive Committee.

Our Governance strives to be a transparent body, matching the expectations of the Company’s shareholders throughout the world.

Our governance

Pre-owned helicopters

Providing you with the right solution

Discover our selection of pre-owned helicopters.

If you are unable to find the model that suits your needs, contact our team to see how we can help you find the right solution.

Contact us

For inquiries regarding pre-owned aircraft for sale worldwide (except North America), please refer to the information below:

Jean-Baptiste Fruitier

jean-baptiste.fruitier@airbus.com

For inquiries regarding pre-owned aircraft for sale in North America, please refer to the following contact information:

Jeff Donahue

jeff.donahue@airbus.com

The latest from Airbus Helicopters

in the spotlight

-

Press releases Helicopters

New Airbus H160/H175 simulators for Brazil

Airbus has committed to providing full flight H160/H175 simulators for training in Brazil in 2028. -

Stories Helicopters

Send in the Super Puma for aerial firefighting operations

-

Stories Helicopters

H140: finding the perfect balance on the cutting edge

-

Stories Helicopters

A perfect match - DRF Luftrettung and the Airbus H145

-

Stories Helicopters

The Airbus H175: the further, the better

Airbus Atlantic

A global leader

Airbus Atlantic is a global leader, delivering competitive & innovative solutions in Aerostructures, Pilot seats and Premium passenger seats, for a sustainable aerospace industry. With a business volume of 5.6 billion euros forecasted in 2025, Airbus Atlantic gathers more than 14 000 employees in five countries and three continents.

Building on its highly qualified teams and entrepreneurship spirit, Airbus Atlantic innovates, shapes new standards of industrial excellence and prepares the future for a sustainable and competitive aerospace industry.

Discover more about Airbus Atlantic

Research & Technology at Airbus Atlantic

Airbus Atlantic invests long term in its people and in the research resources needed to prepare for the future with high levels of expertise and cutting-edge technologies.

Located in all the Group’s main production and engineering facilities in France. The Research and Technology (R&T) department works to develop the future technologies that will keep Airbus Atlantic at the forefront of innovation in design and manufacturing.

The life cycle of an aircraft

From development to end-of-life

Airbus has built more than 15,500 commercial aircraft during the company’s 50-plus year history, maintaining a leadership position through a focus on innovation, performance and efficiency.

Learn more about the life cycle of an aircraft: design, test and certification, production, delivery and operating life.

Learn more about the life cycle of an aircraft

A proven international system

The production of Airbus aircraft benefits from a truly international industrial system with cooperation across the company’s global footprint, partnered with a worldwide supply chain.

Airbus has evolved how its airplanes are built. New digital technologies help to deliver on time while maintaining quality, keep flexibility to adjust aircraft production, and reduce the impact of manufacturing activities on the environment for improved sustainability.

Transforming how an aircraft is built

Looking to the future, Airbus is undertaking a major transformation called DDMS (Digital Design Manufacturing & Services), responding to the increasingly competitive marketplace, while also preparing for the next generation of low-emission aircraft.

To achieve this ambition aircraft manufacturing and assembly is evolving to bring in new processes, tools and jobs for a different way to design and build aircraft, while also offering an improved workspace for employees.

With increased modular design and customisation capabilities the next industrial system will leverage higher levels of standardisation and commonality of parts and major components, enabling new Build-To-Stock and Build-to-Order decoupled approaches. In the factories, teams will benefit from even more digital and connected processes, tools and devices. This will enable just-in-time operations and flexibility to produce and assemble aircraft faster, in a cleaner, more efficient and even safer environment. They will perform activities with more added value, supported by robots and using lighter-weight tooling.

This ambitious makeover will enable Airbus to adapt production rates more rapidly to meet customer demand, further enhance quality, increase flexibility in the delivery of aircraft, lower the environmental impact by decarbonising manufacturing activities, and reduce costs.

From co-design to automation to decarbonisation

Four concepts will be the drivers for Airbus’ industrial system transformation: co-design; digitalisation of manufacturing processes and tools; robotics and decarbonisation.

Co-design is all about designing the new programmes at the same time as Airbus designs the industrial system, integrating the needs of manufacturing and involving the supply chain in this overall process.

Digitalisation of manufacturing processes and tools will ensure end-to-end data continuity – from engineering to manufacturing. This will facilitate data continuity and flow, transparent collaboration, enabling substantial gains in terms of performance and efficiency, lead times, standardisation and access to operational information.

The increasing use of robotics in Airbus’ industrial system will substantially contribute to reduce production costs and increase quality standards. It will also enable teams in the manufacturing areas to concentrate on added-value activities, letting robots do the repetitive, difficult or low added-value tasks, increasing safety and overall well-being in the manufacturing areas.

The industrial system’s transformation is also driven by the ambition of Airbus to decarbonise its overall industrial activities, further limiting their impact on the environment. This includes reducing or eliminating harmful materials and chemicals on the shop floors, cutting back on the use of water and energy in manufacturing areas, and increasing the use of 3D printed parts – even with reused materials.

Airframes

At the heart of all aircraft

Aerostructures

At the heart of all Airbus aircraft are aerostructures – the major assembly elements that come together in creating their airframes, including fuselage sections, wing components and flight control surfaces, along with fairings, doors and bulkheads. The high quality and precision build of these aerostructures – along with the speed of their assembly – are critical in maintaining Airbus’ ability to deliver optimised, efficient aircraft for operators around the world.

In addition to working with key global supply chain partners, Airbus is constantly looking to strengthen its own core airframe assembly activities to meet the increasing demands of the industry in terms of technological evolution, new skills development and competitiveness.

For fuselage aerostructures activities, which previously were mostly performed both in Airbus plants and in former Airbus subsidiaries STELIA Aerospace and Premium AEROTEC, part of this journey has involved the creation of two new companies: Airbus Atlantic and Airbus Aerostructures. These two strong businesses will shape the future of Airbus products and the industrial system.

Discover Aerostructures

Airbus Atlantic

Airbus Atlantic, was established on 1 January 2022, gathering forces, resources and means of Airbus Nantes and Montoir-de-Bretagne plants, central functions associated with these activities and STELIA Aerospace sites worldwide. Airbus Atlantic counts 13,000 employees in 5 countries and 3 continents.

Cabin and Comfort

Providing the ultimate passenger experience

Cabin comfort can make a huge difference to the passenger experience and that is why it is a major priority for Airbus. Airbus’ innovative Airspace cabin brand – launched in 2016 – was created with passengers at heart, and built around four key pillars: comfort, ambience, services and design.

Airbus aircraft offer high levels of cabin air quality, state-of-the-art In-Flight Entertainment (IFE) systems, ambient lighting and more personal space - all ensuring that passengers arrive at their destination refreshed and ready to go. Other features make sure that cabin crew are as comfortable and well rested as possible, helping them to give the best possible service to passengers.

Our passenger aircraft cabins

A relaxing environment

Light and design

Airbus cabins are designed to provide a relaxing environment for passengers. A unique and customisable welcome area, the latest in LED technology and acoustic and clean design work together to create the best possible passenger experience.

Ambient lighting

Airbus was the first manufacturer to introduce ambient lighting as a factory fit option on commercial aircraft. Pre-defined lighting scenarios use colours, brightness levels and dynamic transitions to provide a pleasant cabin atmosphere in all phases of flight. For example, this feature can be used to reduce the effects of jet lag by simulating sunrise or sunset – ensuring passengers arrive at their destination refreshed and ready to go.

Contemporary design

Airbus’ aircraft often surprise people by how quiet it is on-board. Acoustic design, spaciousness and contemporary design elements such as straight lines, clean shapes and clear surfaces make a major contribution toward stress-free and restful flights.

Cabin air flow and ventilation

How does it work?

Airbus aircraft offer one of the safest environments with air filtration systems that ensure high levels of cabin air quality for passengers and crew, thanks to a thoroughly designed cabin “Environment Control System” (ECS).

The ECS, which controls and monitors the air quality, temperature and pressure, also ensures that the airflow inside the cabin is constantly moving: it flows from top to bottom at one metre per second. This airflow is optimised to prevent longitudinal movement, so there is no spread between adjacent seat rows.

In addition, during flight the air is constantly entering and leaving the cabin. As fresh air enters the cabin from outside, the same quantity of ‘used’ air from the cabin is expelled overboard via the pressurisation outflow valves, fully renewing the cabin air about every two to three minutes. For comparison, air in hospital rooms and classrooms is exchanged about every 10 minutes and about 20 minutes in offices.

Any recirculated air is first passed through High-Efficiency Particulate Arrestance (HEPA) filters before it is mixed with the fresh air from outside. Overall, the HEPA filters eliminate more than 99.9 percent of particles from recirculated air, ensuring that the mix of fresh and pre-filtered recirculated air is clean and virus-free.

HEPA technology, originally developed for the US military to prevent the spread of airborne radioactive contaminants, has been installed in all Airbus aircraft since 1994. The filters, usually installed close to the centre wingbox in the underfloor area of the cabin, are known for their effectiveness in capturing microscopic airborne particulates covering typical bacteria and viruses.

Freighter Family

Versatile solutions

Freighters and airlifters

The demand for cargo has been boosted by e-commerce, and it is expected that express freight will grow by 4.4% per year and general cargo by 2.7%. Overall, over the next 20 years there will be a need for some 2,470 freighters, of which 940 will be new-build.

Airbus provides a range of freighters with different capacities and capabilities to service the market enabling supply chain networks to transport a full range of cargo – from high-value consumer goods, manufacturing parts to express packages and perishables as well as medical supplies.

Our Freighters portfolio

Get to know the A350F

Shaping the future

The newest freighter coming to the large cargo market is the A350F. Bringing more efficiency with the latest-generation innovations designed to reduce fuel burn and carbon emissions by up to 40% compared to current in service freighters.

The A350F will embark on its first flight in 2025. When it enters service in 2026, the aircraft will be able to carry a payload of up to 111 tonnes over a range of up to 4,700 nm.

Big is Beluga

For oversized cargo loads

BelugaST

Also known as the A300-600ST Super Transporter, for over 20 years the BelugaST fleet played a central role in keeping Airbus’ commercial aircraft production and assembly network at full capacity and offered transport solutions for outsized cargo to the wider commercial freighter market.

BelugaXL

Derived from the versatile A330-200, the six-member BelugaXL fleet supports Airbus’ accelerating production ramp-up. The specially-commissioned airlifters, built by Airbus in Toulouse, France, ferry sub-assemblies and components between 11 destinations around Europe.

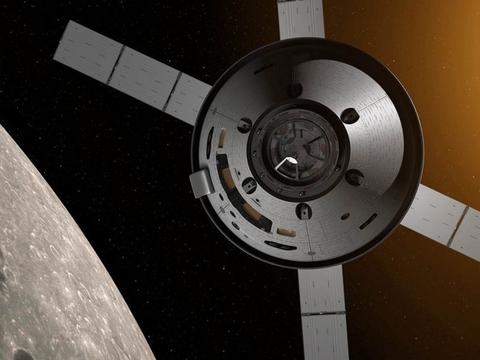

Space ground systems

End-to-end solutions tailored to your needs

For more than 40 years, Airbus has built up a strong expertise in ground systems as a prime contractor for a wide range of customers, from the military to institutions and commercial operators.

We design, integrate and deliver turnkey ground systems, including ground stations, mission control centres, remote user terminals and ground networks, in a highly secured environment. Our mission does not end with delivery. We support our customers all the way through, providing consulting and training services to match the expected level of autonomy.

Direct Receiving Station

Easy access to imagery

Our Direct Receiving Station (DRS) provides direct access to our full constellation of Earth observation satellites.

Our modular and secure turnkey solutions include:

- The infrastructure, i.e. the antenna to receive the telemetry from the satellites

- A terminal to turn telemetry into image products,

- A data management system to display and distribute the data.

We also provide training, customer support, technical assistance and maintenance. This enables customers to manage the entire satellite imagery production chain, including tasking, acquisition, reception and distribution. Customers benefit from unparalleled coverage at special prices, with full flexibility in terms of tasking and download. Our DRS network currently consists of 24 partners worldwide.

Telecommunications satellite anchoring & infrastructure operations

Our global, fully redundant teleports operate 24/7, offering reliable satellite communication services. For customers lacking teleport, backhaul, and anchoring support, we provide secure teleport services to meet their needs.

Equipped with multiple antennas, expert staff, robust security, and power systems, our teleports ensure resource redundancy and cost-effective service. They connect satellite constellations to terrestrial networks, delivering high quality, end-to-end connectivity.

End-user terminals

Our portfolio of satellite communication terminals offers the right solution for your mission. Recognising that today's operations span many different domains, with different requirements for data, voice or both, Airbus offers a comprehensive SATCOM terminal portfolio covering all domains, including On-the-Move (COTM/SOTM) solutions.

We partner with the best terminal manufacturers and invest in our own technology for airborne applications (AirPatrol and Janus).

Network management (NMS and orchestration)

Terrestrial connectivity

Connecting our customers in the harshest environments with terrestrial solutions.

Our wireless and radio networks enable communications in the harshest environments - even where satellite services are not an option. We use a range of commercial wireless technologies, including LTE (Long Term Evolution) for large fixed sites or when you are on the move. Our agile solution is also 5G-ready, enabling radio cells to be deployed in a wider range of environments.

The latest Space news

In the Spotlight

-

Stories Space

Biomass, a satellite to look inside the world’s forests like never before

The ESA Biomass satellite, built by Airbus, monitors forests to evaluate carbon stocks and their impact on climate change. -

Stories Innovation

Improving the world we live in with AI-powered products

-

Press releases Space

Airbus awarded Oberon satellites contract by UK MOD

-

Press releases Space

Airbus-built SpainSat NG-I satellite successfully launched

-

Stories Space

Keeping the lights on for the lunar Gateway HALO module