Airbus promotes the space ecosystem

As Germany’s biggest space player, Airbus people make up around half those working in the space industry in Germany – and we are committed to nurturing the wider space ecosystem.

At Airbus, we are going to help put the next astronaut on the moon using a spaceship propelled by technology made in Germany. Our satellites monitor the world from above to support daily life on Earth and help protect our planet. Our engineers create and run research facilities in space with focus on the ISS.

Focus on Bremen

Bremen is the European centre of competence for human space flight and space robotics. As a trusted partner of the European Space Agency, our highly-skilled employees are contributing to NASA’s Artemis programme which will put the first woman and next man on the Moon. With Orion’s European Service Module, we are the first European company to build a mission-critical module for a U.S. human space flight mission.

Talking of international endeavours, it is our Bremen teams who make sure that when astronauts are working on European components of the International Space Station (ISS) like the Airbus-built Columbus laboratory, everything runs smoothly. Outside the ISS is also where Airbus’ Bartolomeo platform can be found: offering new opportunities for science and research in space.

With an eye to the future, Airbus and the space start-up Voyager Space founded a transatlantic joint venture paving the way to develop, build, and operate Starlab, a commercial space station planned to succeed the ISS. The European Space Agency has signed with Voyager and Airbus a trilateral Memorandum of Understanding, outlining their collaboration for the Starlab space station in the post-ISS era.

Focus on Friedrichshafen

Knowing what’s happening with the weather matters to us all and it is Airbus expertise that helps make this possible. In Friedrichshafen, our engineers are currently developing the second generation of Europe’s MetOp weather satellites – following on from the first MetOps, made by Airbus, which have significantly improved the accuracy of 1 day forecasts.

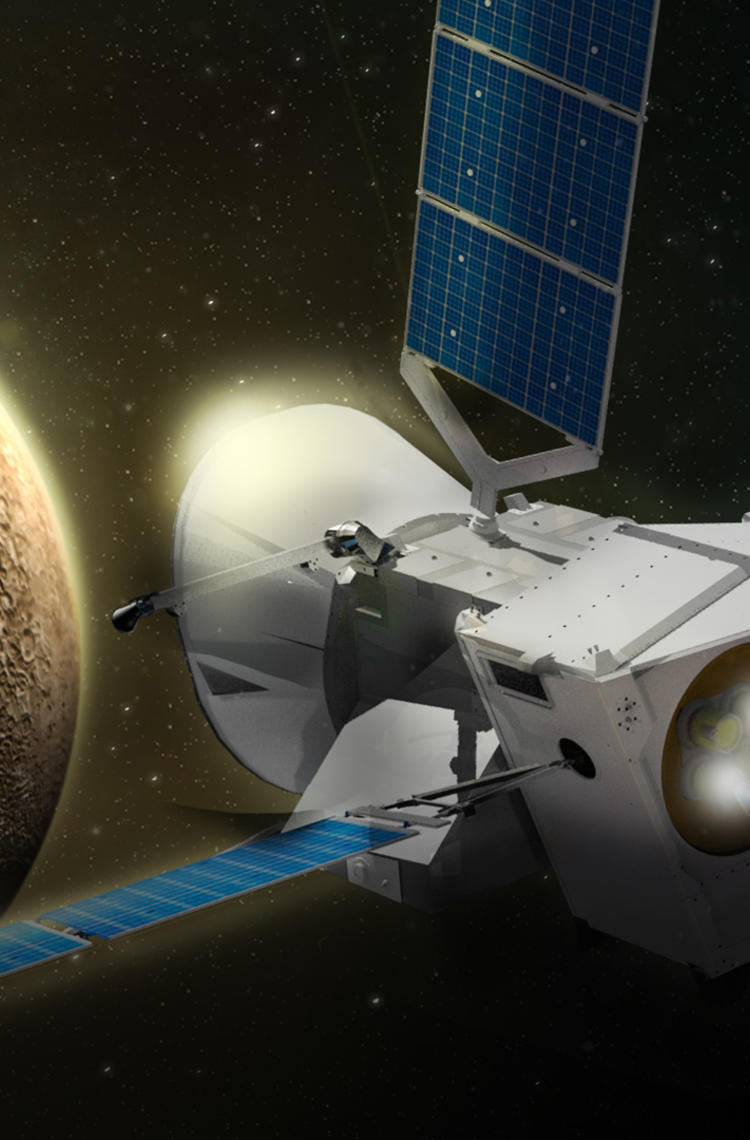

As a key player in the European Union's Copernicus Earth observation programme, the multispectral satellites for the Sentinel-2 mission, the oceanographic satellites for Sentinel-6 and the radar instrument for Sentinel-1 were all crafted at our site on the banks of Lake Constance. While our lead on the joint European-Japanese BepiColombo mission, currently on its way to Mercury, puts the site at the leading edge of space exploration.

Recognised as a world leader in radar satellite technology, the TerraSAR-X and TanDEM-X satellites made in Friedrichshafen can see through clouds and all-weathers to provide round-the-clock monitoring which are delivered as services to customers globally. And, their successors are in the making! The site is also the birthplace for many unique, zero-gravity research facilities used by astronauts on the ISS.

Full production has begun on the six Galileo Second Generation (G2) satellites at Airbus’ site in Friedrichshafen with the arrival of the first satellite Flight Model structure from Beyond Gravity in Zurich. After initial preparation the platforms will be dispatched to other Airbus sites before final integration and testing at Friedrichshafen. The Galileo G2 satellites are scheduled for launch in the coming years to support the initial deployment and validation of the G2 System.

Satellite imagery and data can help to detect and monitor environmental changes such as floods, droughts or fires. Those satellite imagery and data provided by Airbus’ satellites are being processed, monitored and mapped at our sites in Friedrichshafen and Potsdam.

Focus on Ottobrunn/Taufkirchen

Our aerospace site in Ottobrunn/Taufkirchen, near Munich, has not only shaped the history of cutting-edge technology over the last 60 years, it is also actively shaping the future. Today, our solar array production for satellites marks our entry into the age of Industry 4.0, with the site now boasting the largest clean room for optical satellite integration in Germany.

Airbus’s centre of competence for solar arrays has been equipping spacecraft of every class – for weather observation, environmental monitoring, disaster management, navigation, telecommunications satellites - with these highly efficient ‘power plants’ and delivered more than 300 solar arrays worldwide. Some impressive facts: output from a few hundred watts up to 26 kilowatts, 20,000 solar cells per array, wingspan up to 40 metres, maximum weight 145 kilograms. We also support cutting-edge research, especially on science satellites, such as the Jupiter mission (JUICE) or missions to the Sun (Solar Orbiter) and Mercury (BepiColombo).

Our Bavarian site is also home to the Optical Instruments clean room where the Merlin emissions monitoring instrument is being built. This vital Franco-German satellite will measure the methane concentration in Earth’s atmosphere, helping to improve understanding of climate change.

We are also reaching from the stars with the Near Infrared Spectrograph NIRSpec, an instrument capable of detecting the faintest radiation from distant galaxies – made here for use on the U.S. Hubble follow-on, the James Webb Space Telescope.

The SpaceDataHighway provides high-volume data transfer via ultra-broadband laser communications. It enables transfer of time-critical and sensitive information as well as supporting faster and longer access to air and space assets.

Last but not least, site experts in satellite-based navigation help ensure you never get lost on Earth through their work on Galileo and EGNOS.

In a nutshell

Airbus in Germany makes unique contributions to the unique and fascinating world of space.