Discover DynaWorks

DynaWorks is an integrated software platform originally developed by the former Intespace company, later absorbed by Airbus Defence and Space to meet its testing needs. It is an essential tool for design offices, test centres, and stakeholders participating in industrial projects, offering a unique and integrated platform that can be accessed either on-premise or as a SaaS solution.

DynaWorks is a three-in-one platform that provides fast and accurate expertise for data processing. With its integrated database, data processing features, and visualisation tools, the platform covers all types of tests, making it the ideal solution for every step of the product development process. Our collaborative software significantly increases productivity, saves time and effort, and streamlines workflow.

Streamlining industrial testing

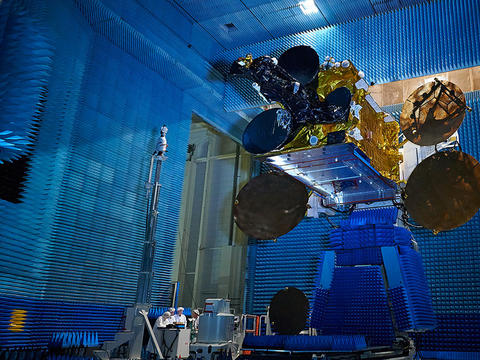

The DynaWorks database is widely used in the aerospace and defence industry by its leading players. It is known for its ability to act across the entire product life cycle, from product development to qualification and operation. This approach is used for testing Telecom and Earth observation satellites as well as commercial wings and military aircraft engines, making it a versatile tool for a variety of purposes. The data stored in the database can be easily retrieved, processed and reported, ensuring fluid communication and interaction between the testing, simulation, and maintenance activities.

DynaWorks figures

DynaWorks is used globally across 90 locations, serving industries such as space, aeronautics, defence, automotive, research, services, and energy.

The main benefits that DynaWorks users can obtain are:

- Rationalized and standardised tools for testing and simulation

- A comprehensive solution for data management and analysis, improved team cooperation

- A central node for environmental testing ensuring traceability

- An open platform for developing flexible interfaces and processing capabilities

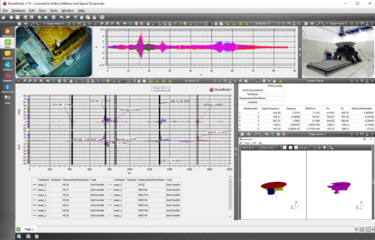

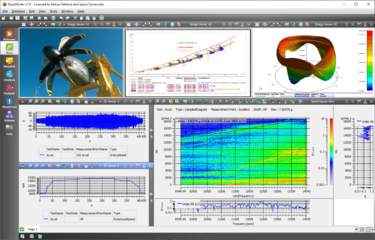

Structural dynamics test

DynaWorks offers a complete set of tools for testing and analysing the mechanical behaviour of system structures :

- Rich signal processing toolboxes for random, sine, acoustic and shock test analysis

- Dedicated workflow for defining vibration tests limits and notching strategies

- RTMVI (Real Time Modal Vibration Identification) method for modal base extraction

- MAC (Modal Assurance Criterion) criteria, test/test and test/simulation comparison tools

- Geometry display for test and mode shapes animation

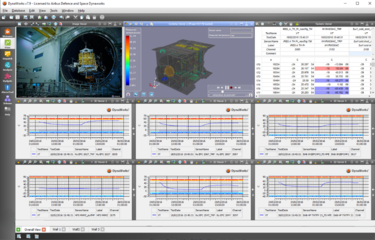

Thermal vacuum test monitoring and analysis

Space simulation in thermal vacuum chambers is crucial for spacecraft qualification, requiring the acquisition of thousands of parameters for real-time or post-test analysis. DynaWorks offers solutions to aggregate this data for test stakeholders (test operators, satellite architects and remote customers).

- DynaThermaNeo handles test preparation and real-time acquisition

- DynaWorks provides real-time display and processing

- DySCo supports 3D model display and test/simulation comparisons

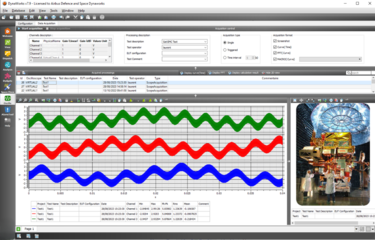

Electrical test

A large number of functional tests must be performed and verified in the context of electrical equipment qualifications like CE Marking, DO160, and ECSS, data is acquired using standard oscilloscopes, which are unable to record large data volumes. To meet these requirements, DynaWorks developed the OscilloToolbox workbench.

- Acquire the data from oscilloscopes (continue, one shot, triggered)

- Store the data with several process options (RAW, Screen capture, FFT, Scripts, …)

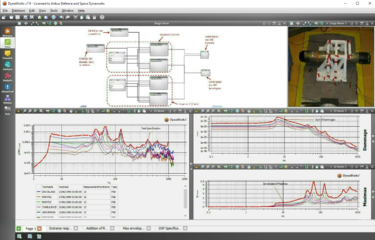

Vibration and shock test tailoring

As a result of 30 years of collaboration with French defence agencies and industrial partners, our shocks and vibrations test tailoring tools enable our customers to:

Without over-testing, comply with various standards:

- GAM (French standards for Wair, Air & Sea)

- ISO (International Organization for Standardization)

- MIL (Military Standard)

- STANAG (NATO Standardization Agreements for procedures, systems, equipment components)

- DO (Aeronautics Standard)

Define their shocks and vibrations specifications based on the real-life conditions of their specimen.

Reduce the number and duration of tests.

Rotating machinery test

As a result of 25 years of collaboration with European aircraft engines manufacturers, our rotating machines tools allow :

- Process engine ratings from tachometer signals

- Generate time or RPM (Rotation per minute) Vs frequency spectrograms

- Process orders and frequencies tracking

- Display campbell diagrams with a full set of utilities (order lines, order extract, frequency extract, cursors extract, peak hold, overall level, envelope)

- Manage engine performance parameters

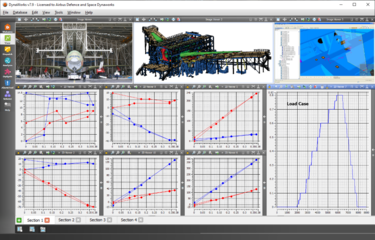

Static and fatigue test

DynaWorks plays a crucial role in aircraft mjor static and fatigue test campaigns by integrating with simulation, test configuration, and sensor tools like Dassault Systems 3DX. It uses data acquisition gateways (e.g., HBM Catman, MTS AeroPro) for real-time monitoring and high-rate data recording. The platform's secure database efficiently manages, retrieves, and compares test data, while its dedicated display and processing tools enhance analysis capabilities.

DynaWorks solution

DynaWorks offers a wide range of tools and applications that can be tailored to your specific needs. Get in touch with our team to create a customised offer that meets your requirements.

Customer testimonials

Contact us

Download documents

Specs and solutions

Specs Produits_DW-V7

Offre DW

Specs and solutions

Specs Produits_DW-V7