Powering humankind’s return to the Moon

More than half a century after man first set foot on the Moon, we are once again striving to reach Earth’s neighbour in space.

Thanks to NASA’s ambitious Artemis programme, humans could soon be walking on the Moon again. The first Artemis mission (performed in 2022) was a very successful uncrewed test flight around the Moon, providing valuable information for future missions.

The next mission, Artemis II, is scheduled for 2026 and will be the first crewed flight, carrying four astronauts around the Moon. Following this, the Artemis III mission aims to land humans on the lunar surface.

During their missions, the Artemis astronauts will investigate the lunar surface and learn how to live and work there.

The Moon is conveniently close to Earth, but also provides the resources needed to reach destinations beyond - making it an ideal starting point to prepare for the next ‘giant leap’: human exploration of Mars.

Airbus is ready to support the establishment of a Lunar ecosystem, contributing with its extensive experience and capabilities in Space exploration, including key technological building blocks, complex systems and solutions.

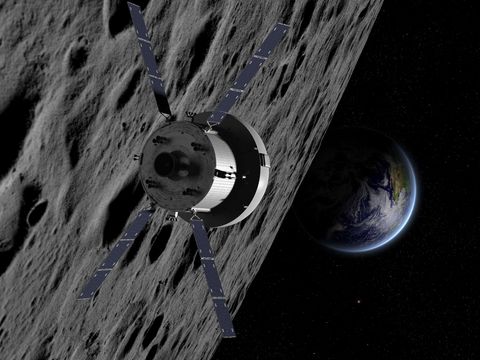

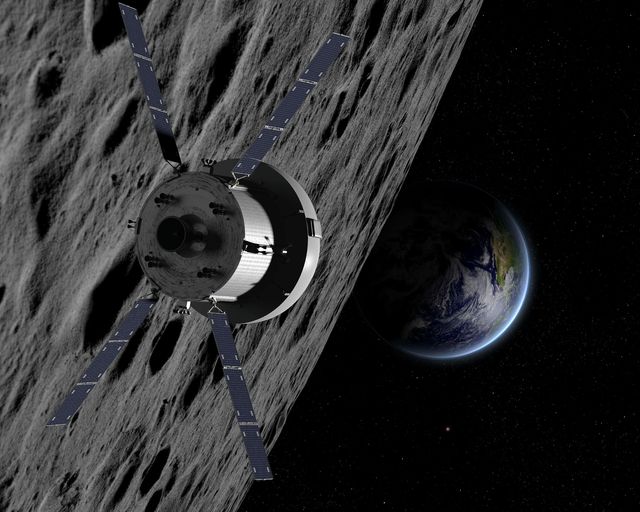

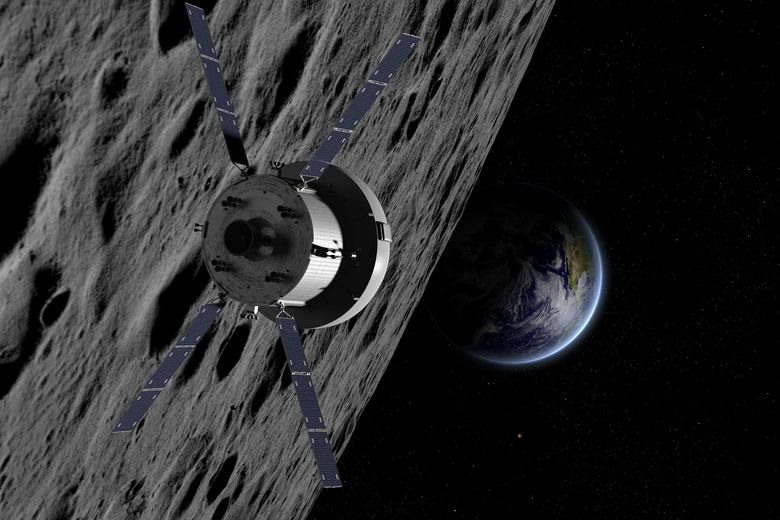

Airbus’ European Service Module powers NASA’s Orion spacecraft

The European Service Module (ESM) plays a vital role in NASA’s Artemis missions to the Moon.

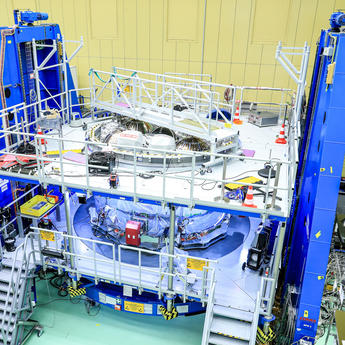

On behalf of ESA, Airbus develops and builds the ESM, which provides propulsion, power, water, oxygen and thermal control.

The first ESM module has already successfully completed its flight in November 2022. ESM-2 and 3 are awaiting their upcoming missions, while ESM 4 through 6 are under construction in the Airbus cleanrooms in Bremen.

ESM is the powerhouse of the Orion spacecraft

Making key resources on the Moon

To stay on the Moon long term, astronauts will need to build permanent habitats and supply facilities. Resources for these needs are available on the Moon: icy water in the polar regions and lunar dust or regolith.

The ROXY (Regolith to OXYgen and Metals Conversion) process, developed by Airbus, can convert regolith into oxygen and metallic materials. This requires no additional materials or consumables from Earth and could revolutionise human space exploration.

This could be at the heart of an integrated value chain using additive layer manufacturing and larger 3D printers to produce a wide range of products and structures ‘Made on the Moon’.

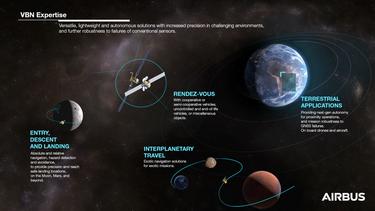

Navigating the future

Airbus is a leading developer of Vision-Based Navigation (VBN) systems, which use optical sensors and state-of-the-art techniques to provide localisation information for moving vehicles - providing a robust alternative when GPS (Global Positioning System) services are unavailable or insufficient.

VBN is relied upon for some of the most exciting – and critical – moments in space exploration: rendezvous (including meetups with orbiting space stations); reentry, descent and landing; and even interplanetary travel. It also has terrestrial applications, supporting aircraft and drones.

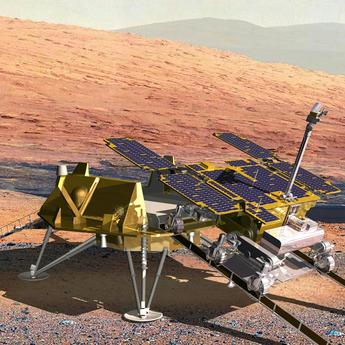

Applications using Airbus’ VBN expertise for orbital rendezvous and on-orbit servicing include the International Space Station supply missions using European Automated Transfer Vehicles (ATV). Rendezvous can also extend to uncontrolled objects, and cover space debris removal around the Earth with the remarkable RemoveDebris mission and its many debris capture prototypes, or rendezvous manoeuvres in the vicinity of Mars with the Mars Sample Return mission.

For detailed information please contact us

The latest space exploration news

In the spotlight

-

Airbus ships fourth European Service Module for Artemis IV

Press Release

Space

Fourth European Service Module (ESM-4) is ready to leave Airbus’ facilities in Bremen, Germany, and be shipped to NASA’s Kennedy Space Center, Florida, USA -

Airbus to design and build ESA’s ExoMars rover lander platform

Press Release

Space

-

Keeping the lights on for the lunar Gateway HALO module

Web Story

Space

-

Orion’s European Service Module 3, the backbone of return to the Moon

Web Story

Space

-

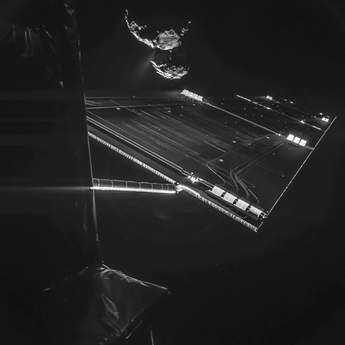

The Rosetta odyssey: first ever comet-chaser

Web Story

Space