Digitising maintenance for end-to-end continuity

How do you digitise and automate maintenance activities? Airbus’ Singapore-based head of technology in APAC Cyrille Schwob is determined to show the industry how.

Cyrille, how did ‘Hangar of the Future’ get off the ground?

The Hangar of the Future project came into existence in February 2016 as a response to the challenges faced by the MRO providers in Singapore due to an ever-increasing level of maintenance activities required by growing fleets in Asia.

With the mass application of digital manufacturing technologies to production assembly lines we were seeing as part of the Industry 4.0 revolution, it became clear to us that that achieving true end-to-end digital continuity for the entire life cycle of an aircraft meant extending digital technologies and principles to maintenance activities.

My role is to oversee the project’s continuous development, making sure we integrate next-generation technologies and develop state-of-the-art business applications. I am a big believer in the Hangar of the Future initiative, and I am far from being alone on this one: the concept has attracted several interested players over the last two years with whom we have discussed and analysed the potentially huge savings it could provide.

What is Hangar of the Future in a nutshell?

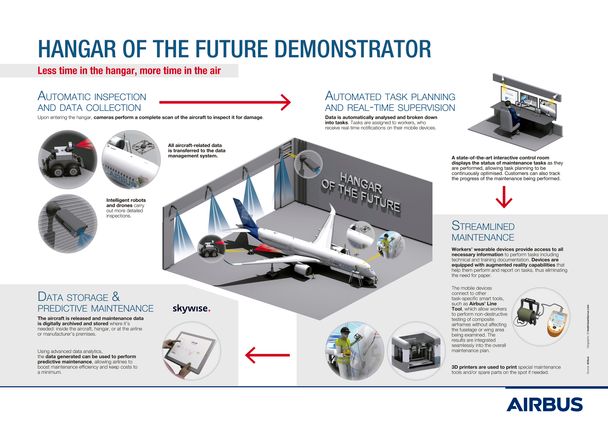

The premise is simple: Hangar of the Future combines various technologies that together speed up maintenance and improve efficiency to be able to cope with more work in less time.

Airlines are already moving more and more towards predictive maintenance and automated inspections to reduce the burden of inventory costs and lead times. This initiative demonstrates how leveraging new digital technologies can transform the MRO industry, which appeals to both MRO centres as well as the technicians who work in them. Maintenance technicians are one of the most in-demand vocations nowadays given the constantly growing number of in-service aircraft, and they welcome solutions that make their job more efficient and enjoyable.

How did you decide which technologies to include?

We started off by analysing real-life use cases provided by our partners in the MRO sector. After an in-depth analysis, we selected technologies that will speed up every step of the maintenance process.

This includes smart, IOT-connected equipment such as collaborative robots, drones, scanners, cameras, non-destructive sensors, couple with Airbus’ open data platform, Skywise.

Skywise collects essential in-service data from the various IT and aircraft systems and offers powerful tools and a framework for conducting analyses. As an example, we are currently using it to correlate various maintenance events to identify patterns that allow us to further optimise distinct maintenance operations.

Why Singapore?

It was really a no-brainer to set up the Hangar of the Future in Singapore, a region where Airbus has fast-growing services presence, important maintenance operations and several key partners, such as ST Aerospace and SIAEC.

Singapore’s innovation ecosystem is an extremely welcoming environment for R&T demos, not to mention the country boasts world renowned universities, such as the Temasek Polytechnic education institution, high-quality research organisations such as ASTAR, and a vibrant start-up scene that enabled us to work with Unabiz.

All of this has been facilitated by a strong partnership with the country’s Economic Development Board (EDB), co-founder of the project.